Advantages and Disadvantages of Plate Heat Exchanger

What is the disadvantage of shell and tube. Only the shell plate of the heat transfer plate of the plate heat exchanger is exposed to the atmosphere so the heat dissipation loss is negligible and no insulation measures are required.

Advantages And Disadvantages Of A Plate Heat Exchanger Stoll

How to buy a quality plate heat exchanger.

. Plate heat exchangers are more efficient than tube heat exchangers due to the high turbulent flow created in patented plate designs. Difficulty in Finding Leakage. Advantages and disadvantages of plate heat exchangers.

First long gaskets are needed. Advantages And Disadvantages Of Plate Fin Heat Exchanger. No extra space is required for dismantling.

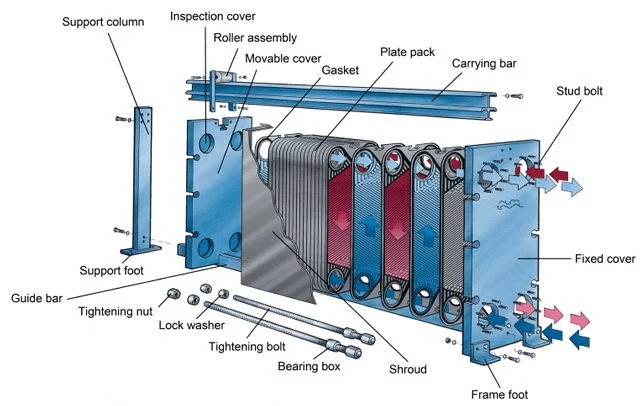

If replacement is needed the plates may be removed conveniently as well. 1 High heat transfer coefficient. Free easy returns on millions of items.

As long as the number of plates is increased or decreased the purpose of increasing or decreasing the heat exchange area can be achieved. Besides being highly efficient it is easy to install and maintain. Shop With OFS Today.

Its yield is low. Capacity can be increased by introducing plates in pairs. Turbulent flow help to reduce deposits which would.

1 Poor sealing and easy to leak. The purpose for it is that the way toward completing pressing factor tests isnt pretty much as. Second leakage is probable.

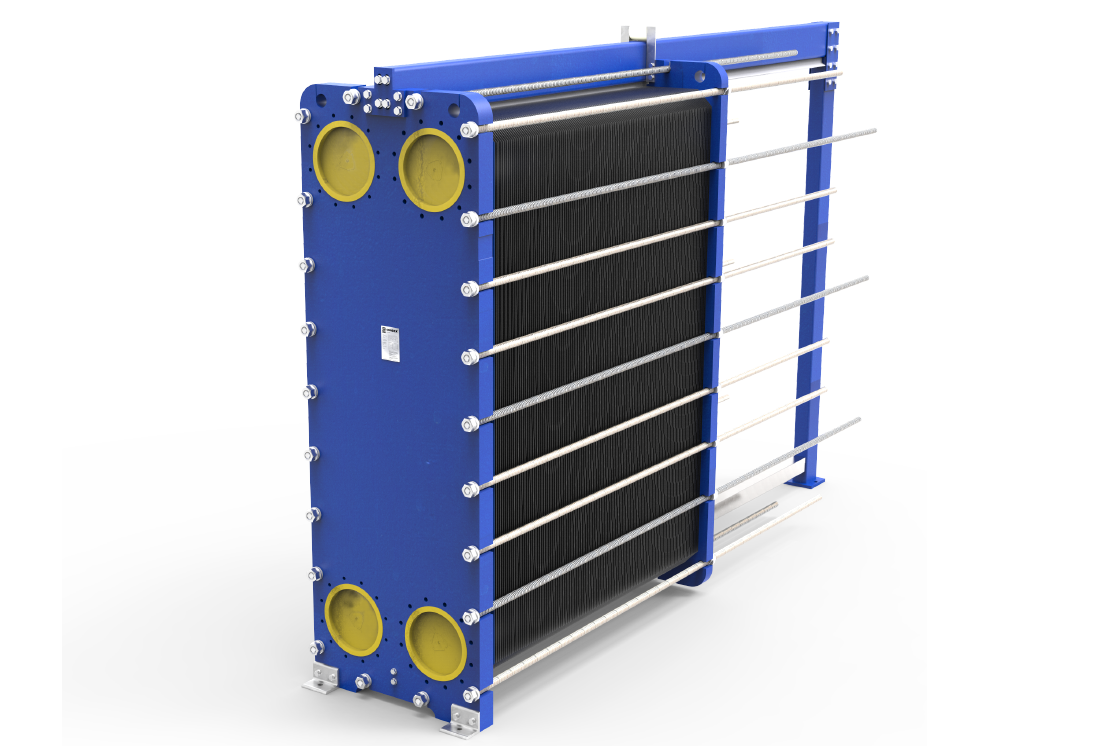

They have a small footprint that requires little to no maintenance space. The frame is much heavier and the plate heat exchanger is generally only about 15 of the weight of the shell-and-tube type. The fluid allows a higher flow rate in the spiral plate and the fluid flows in the spiral direction and the stagnant layer is thin so the heat transfer coefficient is large and the heat transfer.

The selection of plate heat exchanger plates is very important and the service life depends on it. Modern plate heat exchangers use pressed plates which are less expensive than the welded plates used on early models. The counter-flow heat exchanger provides the most thermally effective arrangement for recovery of heat or cold from process streams.

They occupy 20 30 of the volume used by tube heat exchangers. Plate exchangers typically have a larger coefficient of heat transfer as they have more contact area between fluids. Plate heat exchangers mainly use metal plates so the price of raw materials is cheaper than the same metal pipes.

Ad Over 1 Million Products 7000 Trusted Brands Hassle Free Returns. Simple and Compact in size. Can be easily cleaned.

Compared with the traditional shell-and-tube heat exchanger which is bulky and occupies a large area the plate heat exchanger is light in weight and occupies a small area. The plate heat exchanger has a small flow path the plate is a corrugation shape and the section change is complicated so that the fluid flow direction and velocity are constantly changed the fluid disturbance is increased and the turbulence can be achieved at a small. Lets check it out below.

Advantages of plate heat exchanger. A counter flow arrangement is thermodynamically. A huge disadvantage of a PCHE heat exchanger plate is that it is very hard to track down spillage in it.

Many heat exchanges have even been modified with ease of cleaning in mind. For example the heat transfer surface of the spiral plate heat exchanger with a diameter of 1500mm and a height of 1200mm can reach 130m2. It is suitable for chemical petroleum solvent pharmaceutical food light industry textile metallurgy steel rolling coking.

Plate Heat Exchangers For Your Alternative Energy Needs. It has been widely used in metallurgy mining petroleum chemical industry electric power medicine food. They are lighter and cheaper than tube heat exchangers in terms of material used.

The advantages of a Plate heat exchanger are numerous. Ad Shop Now From Our Wide Selection of Heating Equipment and Supplies. Leaking plates can be removed in pairs if necessary without replacement.

Pressed plates are also more resistant to corrosion and chemical reactions that would weaken the heat exchanger and require more frequent replacement. In a counter flow heat exchanger the two fluids flow parallel to each other but in opposite directions. Below are some advantages of using a plate heat exchanger over the ever-popular shell and tube heat exchanger.

Introduction to the advantages and disadvantages of plate heat. Disadvantages of plate heat exchangers. The plate heat exchanger plate is of good material and has little corrosion which makes its fouling coefficient value smaller.

The plate heater can even be placed on a roof. A plate heat exchanger is a good option for many industrial applications. The plates are removable thus making it easy to clean.

Read customer reviews find best sellers. The spiral plate heat exchanger is a high-efficiency heat exchanger device which is suitable for steam-vapor vapor-liquid liquid-liquid and liquid heat transfer. Plate Heat Exchangers For Your Alternative Energy Needs.

There is basically no welding and the frame can be completely. It has the characteristics of high heat exchange efficiency small heat loss compact and lightweight structure small floor area and long service life. Free shipping on qualified orders.

Heat transfer efficiency is more. Ad Browse discover thousands of brands. The stainless steel plate heat exchanger covers an area of about 15 to 18 of the shell and tube heat exchanger.

2 It is easy to change the heat exchange area or flow combination. During the installation process of the plate heat exchanger the choice of the interface form is also very important. If this type of heater is in your plant consider a heat exchanger that is made from a similar material.

And lastly operation costs as well as investment should also form part of the. Plate heat exchanger is a high-efficiency heat exchanger made of a series of corrugated metal sheets. Explore Our Wide Selection of Heating Supplies and Accessories to Find Your Next Solution.

Advantages And Disadvantages Of Spiral Plate Heat Exchanger. The main disadvantages of plate heat exchangers are classified into three.

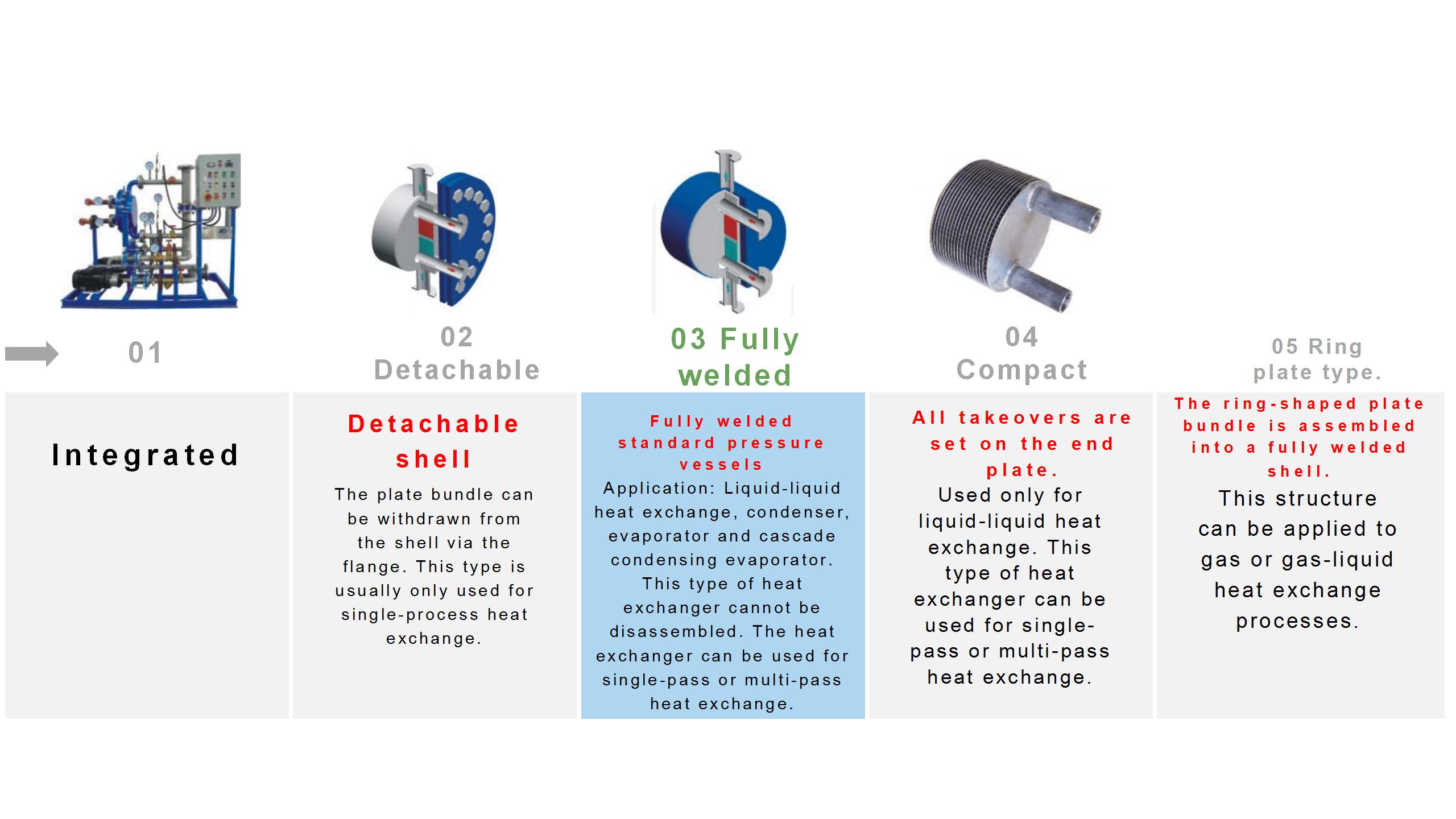

Plate And Shell Heat Exchangers Are Also Classified

Maintaining A Plate Heat Exchanger 2002 03 01 Process Heating

Comments

Post a Comment